Views: 0 Author: Site Editor Publish Time: 2025-09-08 Origin: Site

The production of TSY soy sauce is essentially a complex biochemical process that uses microorganisms such as Aspergillus oryzae, yeast, and lactic acid bacteria to ferment raw materials like soybeans and wheat.

1: Raw material Selection and Ratio

Main raw materials: soybeans (or defatted soybeans), wheat, salt, water.

2: Raw material Treatment

Soybean processing: After washing the soybeans, soak them in warm water until they fully absorb water and expand. Then, through a rotating cooking pot, it is cooked under high-pressure steam to moderately denature the protein, making it easier to be decomposed by enzymes.

Wheat processing: After being washed, the wheat is roasted in a pan until it becomes fragrant and golden brown. Then crush it into coarse granules. The purpose of roasting is to produce aromas (malt aroma, caramel aroma) and to destroy the starch structure of wheat, facilitating subsequent saccharification.

3: Mixing and Inoculation (Mixing & Inoculation)

Mix the steamed soybeans and the roasted and crushed wheat evenly and cool them to about 40℃. Then evenly mix in the starter culture (containing a large amount of purebred Aspergillus oryzae spores).

Phase Two: Fermentation

4: Fermentation Management

The sauce mash will undergo a long fermentation process ranging from several months to half a year in the fermentation tank.

Phase Three:Pressing & Refining

The objective of this stage is to separate the liquid (raw soy sauce) in the fermented mash from the solid residue and sterilize and season it.

5: Pressing

The mature mash is loaded into a press (bag press or large continuous press), and a huge pressure is applied to separate the Raw Soy Sauce from the Soy Cake. The sauce residue can be used as animal feed.

6: Sedimentation & Filtration

The raw soy sauce squeezed out is first left to stand and settle, allowing a small amount of fine particles to settle at the bottom. Then, it passes through a plate and frame filter or other precision filtration equipment to remove all suspended solids and obtain clear and transparent soy sauce liquid.

7: Blending & Pasteurization

Blending: According to different product standards (such as light soy sauce and dark soy sauce), add different additives.

Cooking: Heat the soy sauce to 70-80℃ and perform low-temperature pasteurization.

Kill the remaining microorganisms and yeast, terminate the fermentation and stabilize the quality. Generate new aroma substances and harmonize flavors. Make the remaining proteins flocculate and make the soy sauce clearer.

8:Quality Inspection

TSY foodstuff pays close and careful attention to quality control at each step of soy sauce production. Each batch of products must undergo strict sensory evaluation (color, aroma, taste) and physical and chemical testing (amino acid nitrogen, salt content, pH value, etc.) before leaving the factory.

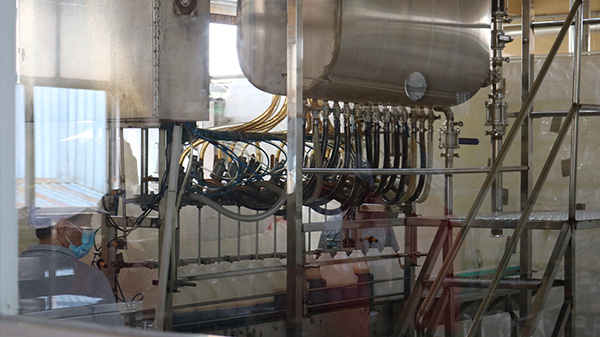

9: Disinfecting & Filling

On the automated assembly line, bottles of glass that have undergone strict cleaning and high-temperature disinfection are filled with dark brown soy sauce.

After sterilization, the soy sauce can be automatically filled in a sterile environment upon cooling.

|  |

Through the above complex process, the original components of soybeans and wheat in TSY soy sauce are perfectly transformed into a unique flavor of soy sauce that harmonizes the five flavors of freshness, saltiness, sweetness, sourness and bitterness, and has a rich aroma.

content is empty!