It is a Umami Light Soy Sauce from China which is natural fermented directly with strong and pure natural flavor of preserved beans. Using soybeans or black beans and flour as the main raw materials, artificially connected to the seed koji, through natural exposure, fermentation.

| Color | Bright, light red brown color with golden |

| Flavor | Salty and Fresh Good Taste, and have a little sweet, Strong Sauce Flavor |

| Purpose | For enhancing flavor, usually served for cooking dishes and preparing cooking or cold dishes. |

| Ingredient | Water, Non-GMO extract of soya beans, Salt, Sugar, Wheat Flour |

| Serving Suggestion | Perfect for stir-frying dishes, rice dishes and as marinade for meats, fish and vegetable dishes. |

| Nutrition information | Energy 126KJ/30KCAL, Protein:4.5g, Carbohydrate 2.9g, Sodium 6340mg |

| Shelf Life | 2 years |

| Storage | Close the lid tightly and keep refrigerated after use. |

| Delivery Time | 15-20days |

| Certificate | HACCP, BRC, IFS, HALAL, KOSHER, ISO |

It is a Umami Light Soy Sauce from China which is natural fermented directly with strong and pure natural flavor of preserved beans. Using soybeans or black beans and flour as the main raw materials, artificially connected to the seed koji, through natural exposure, fermentation.

| Color | Bright, light red brown color with golden |

| Flavor | Salty and Fresh Good Taste, and have a little sweet, Strong Sauce Flavor |

| Purpose | For enhancing flavor, usually served for cooking dishes and preparing cooking or cold dishes. |

| Ingredient | Water, Non-GMO extract of soya beans, Salt, Sugar, Wheat Flour |

| Serving Suggestion | Perfect for stir-frying dishes, rice dishes and as marinade for meats, fish and vegetable dishes. |

| Nutrition information | Energy 126KJ/30KCAL, Protein:4.5g, Carbohydrate 2.9g, Sodium 6340mg |

| Shelf Life | 2 years |

| Storage | Close the lid tightly and keep refrigerated after use. |

| Delivery Time | 15-20days |

| Certificate | HACCP, BRC, IFS, HALAL, KOSHER, ISO |

Steamed sushi umami soy sauce, also known as "Unagi no Tare" or "Eel Sauce," is a specialized type of soy sauce that is used primarily for flavoring and glazing dishes like eel sushi (unagi) and other grilled or steamed dishes. Here are some of its features:

1. Umami Flavor: This sauce is specifically crafted to enhance the umami (savory) flavor of dishes. It has a deep, rich, and complex taste profile that adds depth to the overall flavor of the dish.

2. Sweetness: Steamed sushi umami soy sauce is known for its sweet undertones. It typically contains sugar or a sweetener like mirin (sweet rice wine), which balances the saltiness of the soy sauce.

3. Viscous Texture: It has a thicker, syrupy consistency compared to regular soy sauce. This thickness helps it adhere to the surface of grilled or steamed dishes, creating a glossy finish.

4. Dark Color: The sauce often has a dark brown to caramel color due to the sugar content and caramelization during cooking.

5. Caramelized Notes: Steamed sushi umami soy sauce can have a subtle caramelized or smoky flavor, which complements grilled or steamed ingredients such as eel.

6. Glazing and Dipping: It is primarily used as a glaze for grilled eel (unagi) or freshwater eel (anago) sushi. Additionally, it can be served as a dipping sauce for other dishes like tempura or grilled meats.

7. Customary with Eel Dishes: It is most commonly associated with eel dishes in Japanese cuisine, where it enhances the flavor and imparts a sweet and savory glaze to the eel.

8. Versatile Ingredient: While traditionally used for eel, some chefs and home cooks also use it as a flavor enhancer for other grilled or steamed dishes to impart a unique umami sweetness.

9. Balanced Flavor: It strikes a balance between sweet and savory flavors, making it a popular choice for dishes that benefit from this harmonious blend.

Steamed sushi umami soy sauce is not typically used as a general-purpose soy sauce. Its unique flavor and viscosity make it ideal for specific applications, particularly in Japanese cuisine, where it elevates the taste of grilled and steamed dishes.

Steamed sushi umami soy sauce, also known as "Unagi no Tare" or "Eel Sauce," is a specialized type of soy sauce that is used primarily for flavoring and glazing dishes like eel sushi (unagi) and other grilled or steamed dishes. Here are some of its features:

1. Umami Flavor: This sauce is specifically crafted to enhance the umami (savory) flavor of dishes. It has a deep, rich, and complex taste profile that adds depth to the overall flavor of the dish.

2. Sweetness: Steamed sushi umami soy sauce is known for its sweet undertones. It typically contains sugar or a sweetener like mirin (sweet rice wine), which balances the saltiness of the soy sauce.

3. Viscous Texture: It has a thicker, syrupy consistency compared to regular soy sauce. This thickness helps it adhere to the surface of grilled or steamed dishes, creating a glossy finish.

4. Dark Color: The sauce often has a dark brown to caramel color due to the sugar content and caramelization during cooking.

5. Caramelized Notes: Steamed sushi umami soy sauce can have a subtle caramelized or smoky flavor, which complements grilled or steamed ingredients such as eel.

6. Glazing and Dipping: It is primarily used as a glaze for grilled eel (unagi) or freshwater eel (anago) sushi. Additionally, it can be served as a dipping sauce for other dishes like tempura or grilled meats.

7. Customary with Eel Dishes: It is most commonly associated with eel dishes in Japanese cuisine, where it enhances the flavor and imparts a sweet and savory glaze to the eel.

8. Versatile Ingredient: While traditionally used for eel, some chefs and home cooks also use it as a flavor enhancer for other grilled or steamed dishes to impart a unique umami sweetness.

9. Balanced Flavor: It strikes a balance between sweet and savory flavors, making it a popular choice for dishes that benefit from this harmonious blend.

Steamed sushi umami soy sauce is not typically used as a general-purpose soy sauce. Its unique flavor and viscosity make it ideal for specific applications, particularly in Japanese cuisine, where it elevates the taste of grilled and steamed dishes.

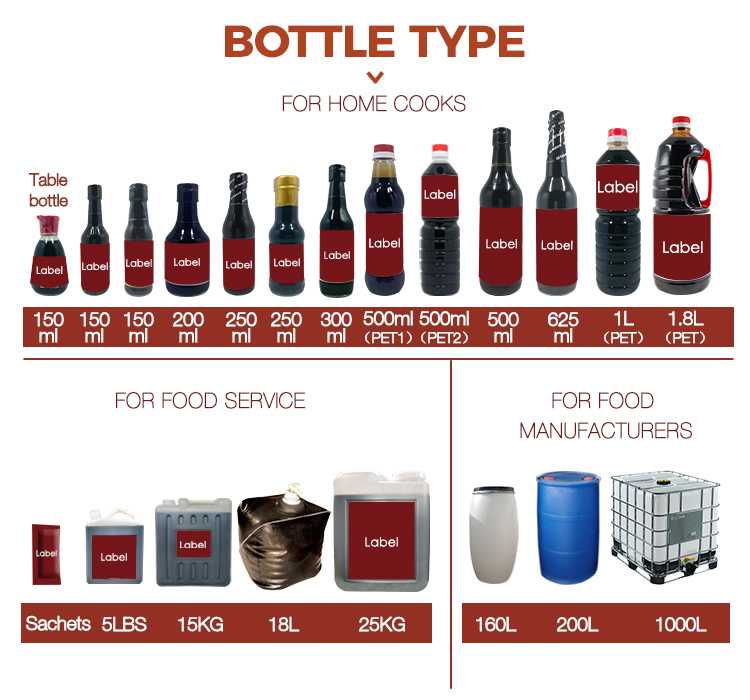

| SPECIFIATION PER CTN | BOTTLE TYPE | CTNS/20'GP |

| 150ml*12btls/box*4boxes | Glass bottle | 1010 |

| 150ml*24btls | Table bottle | 1855 |

| 200ml*24btls | Glass bottle | 1550 |

| 250ml*24btls | Glass bottle | 1550 |

| 300ml*12btls | Glass bottle | 1550 |

| 500ml*12btls | Glass bottle | 1550 |

| 625ml*12btls | Glass bottle | 1330 |

| 1000ml*12btls | Plastic bottle | 1224 |

| 1.86L*6jar | Plastic jar | 1400 |

| 5L*4jar | Plastic jar | 756 |

| 8L*2jar | Plastic jar | 1150 |

| 18L*1bag/box | Faucet soft bags | 1008 |

| 15kg*2drum | Plastic drum | 700 |

| 25kg*1drum | Plastic drum | 800 |

| 160L*1drum | Plastic drum | 100 |

| 200L*1drum | Plastic drum | 80 |

| 1000L*1drum | Plastic drum | 20 |

* If you have other needs, please consult us.

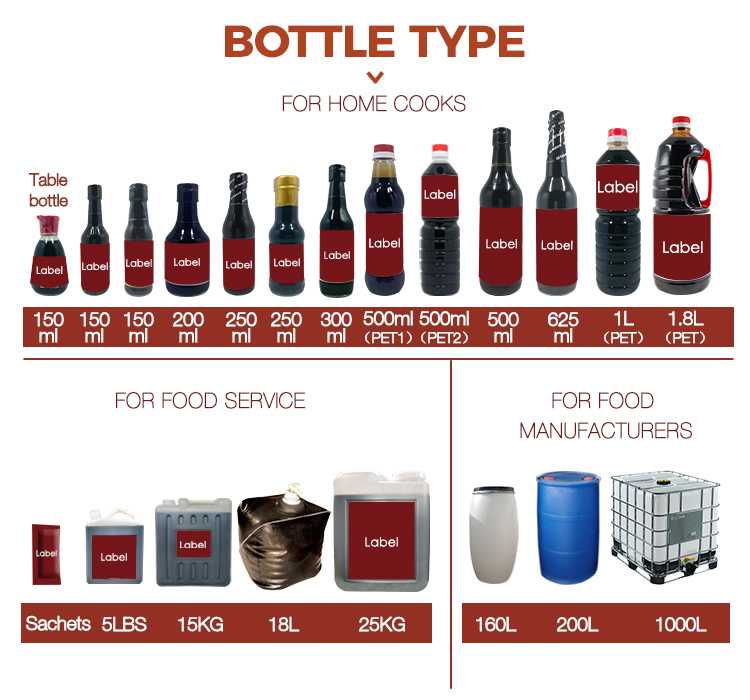

| SPECIFIATION PER CTN | BOTTLE TYPE | CTNS/20'GP |

| 150ml*12btls/box*4boxes | Glass bottle | 1010 |

| 150ml*24btls | Table bottle | 1855 |

| 200ml*24btls | Glass bottle | 1550 |

| 250ml*24btls | Glass bottle | 1550 |

| 300ml*12btls | Glass bottle | 1550 |

| 500ml*12btls | Glass bottle | 1550 |

| 625ml*12btls | Glass bottle | 1330 |

| 1000ml*12btls | Plastic bottle | 1224 |

| 1.86L*6jar | Plastic jar | 1400 |

| 5L*4jar | Plastic jar | 756 |

| 8L*2jar | Plastic jar | 1150 |

| 18L*1bag/box | Faucet soft bags | 1008 |

| 15kg*2drum | Plastic drum | 700 |

| 25kg*1drum | Plastic drum | 800 |

| 160L*1drum | Plastic drum | 100 |

| 200L*1drum | Plastic drum | 80 |

| 1000L*1drum | Plastic drum | 20 |

* If you have other needs, please consult us.

Steamed sushi umami soy sauce is a specialized sauce with a unique flavor profile. The production process involves several steps:

1. Base Soy Sauce: The process typically starts with a base soy sauce, which is made from soybeans, wheat, salt, and water. This base soy sauce can be regular soy sauce or a specific type prepared for this purpose.

2. Sweetener: One of the defining characteristics of steamed sushi umami soy sauce is its sweetness. Sugar or a sweetener like mirin (a sweet rice wine) is added to the base soy sauce. The amount of sweetener used can vary depending on the desired level of sweetness.

3. Caramelization: The sauce is heated and simmered, allowing the sugar to caramelize. This caramelization process not only adds sweetness but also imparts a dark, rich color and a hint of smokiness to the sauce.

4. Umami Enhancement: To enhance the umami flavor, certain ingredients like bonito flakes, dried kombu (kelp), or even sake may be added. These ingredients contribute to the complexity of the sauce's flavor.

5. Reduction: The sauce is simmered and reduced to thicken its consistency. This reduction process creates a thicker, syrupy texture that clings well to the surface of dishes.

6. Straining: After simmering and reducing, the sauce is typically strained to remove any solid particles or impurities. This ensures a smooth and glossy final product.

7. Cooling: Once the desired consistency and flavor are achieved, the sauce is cooled to room temperature or slightly chilled.

8. Bottling: The finished steamed sushi umami soy sauce is then bottled and sealed for distribution and use.

It's important to note that there can be variations in the production process depending on the specific recipe. The key is to strike a balance between sweetness and umami while achieving the desired thickness and flavor complexity that makes this sauce ideal for glazing and enhancing the taste of dishes like eel sushi.

Steamed sushi umami soy sauce is a specialized sauce with a unique flavor profile. The production process involves several steps:

1. Base Soy Sauce: The process typically starts with a base soy sauce, which is made from soybeans, wheat, salt, and water. This base soy sauce can be regular soy sauce or a specific type prepared for this purpose.

2. Sweetener: One of the defining characteristics of steamed sushi umami soy sauce is its sweetness. Sugar or a sweetener like mirin (a sweet rice wine) is added to the base soy sauce. The amount of sweetener used can vary depending on the desired level of sweetness.

3. Caramelization: The sauce is heated and simmered, allowing the sugar to caramelize. This caramelization process not only adds sweetness but also imparts a dark, rich color and a hint of smokiness to the sauce.

4. Umami Enhancement: To enhance the umami flavor, certain ingredients like bonito flakes, dried kombu (kelp), or even sake may be added. These ingredients contribute to the complexity of the sauce's flavor.

5. Reduction: The sauce is simmered and reduced to thicken its consistency. This reduction process creates a thicker, syrupy texture that clings well to the surface of dishes.

6. Straining: After simmering and reducing, the sauce is typically strained to remove any solid particles or impurities. This ensures a smooth and glossy final product.

7. Cooling: Once the desired consistency and flavor are achieved, the sauce is cooled to room temperature or slightly chilled.

8. Bottling: The finished steamed sushi umami soy sauce is then bottled and sealed for distribution and use.

It's important to note that there can be variations in the production process depending on the specific recipe. The key is to strike a balance between sweetness and umami while achieving the desired thickness and flavor complexity that makes this sauce ideal for glazing and enhancing the taste of dishes like eel sushi.

Q1: Are you a genuine manufacturer or a trading company?

A: TSY are an unadulterated original manufacturer. We have our own modern production base, complete production lines and mature brewing techniques. Customers are welcome to visit our factory for on-site inspection and to witness the entire production process from raw materials to finished products with their own eyes.

Q2: What is the production capacity and output of the factory? Can large orders be met?

A: Our TSY factory is equipped with multiple automated production lines, which can efficiently meet the demands of large domestic and international orders, and ensure a stable supply of goods and on-time delivery.

Q3: What quality certifications and quality control systems does the factory have?

A: We attach great importance to product quality and safety and have obtained international food safety management system certifications such as HALAL, HACCP, KOSHER, and FDA. Our quality control laboratory conducts strict full-process testing on raw materials, semi-finished products and finished products to ensure that every batch of products meets the standards.

Q4: Is customization (OEM/ODM) service acceptable? What is the minimum order quantity (MOQ)?

A: Sure! We offer professional OEM (Original Equipment Manufacturer) and ODM (Original Design Manufacturer) services, and can customize product specifications, formulas, labels and packaging according to customer requirements. The specific minimum order quantity depends on the product type and packaging method. Our sales team will provide you with flexible solutions.

Q5: What is the price of the product? Could you provide samples?

A: We insist on providing products with high cost performance. Prices vary depending on product specifications, order quantities and customization requirements. We offer free samples for you to taste and test. You only need to bear the shipping cost so that you can personally confirm our quality.

Q1: Are you a genuine manufacturer or a trading company?

A: TSY are an unadulterated original manufacturer. We have our own modern production base, complete production lines and mature brewing techniques. Customers are welcome to visit our factory for on-site inspection and to witness the entire production process from raw materials to finished products with their own eyes.

Q2: What is the production capacity and output of the factory? Can large orders be met?

A: Our TSY factory is equipped with multiple automated production lines, which can efficiently meet the demands of large domestic and international orders, and ensure a stable supply of goods and on-time delivery.

Q3: What quality certifications and quality control systems does the factory have?

A: We attach great importance to product quality and safety and have obtained international food safety management system certifications such as HALAL, HACCP, KOSHER, and FDA. Our quality control laboratory conducts strict full-process testing on raw materials, semi-finished products and finished products to ensure that every batch of products meets the standards.

Q4: Is customization (OEM/ODM) service acceptable? What is the minimum order quantity (MOQ)?

A: Sure! We offer professional OEM (Original Equipment Manufacturer) and ODM (Original Design Manufacturer) services, and can customize product specifications, formulas, labels and packaging according to customer requirements. The specific minimum order quantity depends on the product type and packaging method. Our sales team will provide you with flexible solutions.

Q5: What is the price of the product? Could you provide samples?

A: We insist on providing products with high cost performance. Prices vary depending on product specifications, order quantities and customization requirements. We offer free samples for you to taste and test. You only need to bear the shipping cost so that you can personally confirm our quality.